C . BS series Angular Contact Ball Bearing Details

Series Introduction

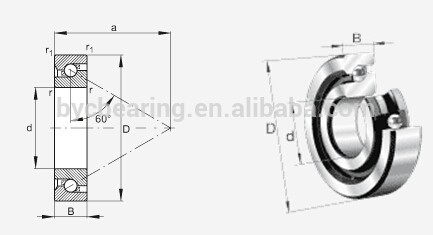

Screw drive bearing-BS series:BS series(Non-ISO metric).Ball screw bearing is single direction angular contact ball bearing with 60 degree.The bearing can bear axial load in single direction and certain radical load. the bearings is mainly installed on ball screw of machine tool feed systems,two to four row arrangements are used in common ways.The back-to-back duplex arrangement is commonly used because it allows acquisition of the specified preload by tightening the inner ring. The face-to-face duplex arrangement may be used if more precise alignment is required. Or universal ground set combination bearings are also available(Suffix G).,this permits the use of random combinations where two or more bearings are mounted. ball screw support bearings are generally lubricated with grease especially the double seals one packed with grease before sending.

Series Model No.

"BS1547TN1 BS1747TN1 BS2047TN1 BS2562TN1 BS3062TN1 BS3072TN1 BS3572TN1 BS4072TN1 BS4090TN1 BS4575TN1 BS45100TN1 BS50100TN1 BS5590TN1 BS55100TN1 BS55120TN1 BS60120TN1 BS75110TN1 BS100150TN

Applications

Angular contact ball bearings for screw drives have high accuracy, high load carrying capacity, high rigidity, low friction, are easy to fit and maintenance-free or low-maintenance advantages.

D . BS series Angular Contact Ball Bearing Installation & Cautions

"Installation:

To obtain the best possible performance of the bearings, installation must be performed very carefully in ultra clean conditions.

Errors during fitting of ball bearings can jeopardize the best design and create high repair and maintenance costs. We would like to give some advise for proper mounting of bearings:

The workshop should be dust free with low humidity, no compressed air or machining is allowed.

Only unpack bearings immediately before installation. If grease is required it should be applied at this time, with a syringe. Do not use fingers or a spatula.

The use of a syringe is recommended to inject the grease right between the balls into the ball/raceway area. Nearly all standard greases are compatible to our rust preventive, so in most cases it is not necessary to wash the bearings prior to greasing. The only exceptions are special greases, based on silicone or fluorocarbon oils or PTFE-thickeners. They require a clean oil free surface to obtain good adhesion of the grease.

Never clean the bearings in ultra sonic devices! Allow the rust preventive to dissolve in a gasoline bath by slowly moving the bearings."